Old World Mashing

/Lisa and I began brewing separately, but both of us began with extract batches of beer. Over the years, our process has changed to an all grain set-up. We currently have a 10 gallon cooler for a mash tun, a 10 gallon kettle, and a Blichmann burner. A simple set up, but not always simple beers.

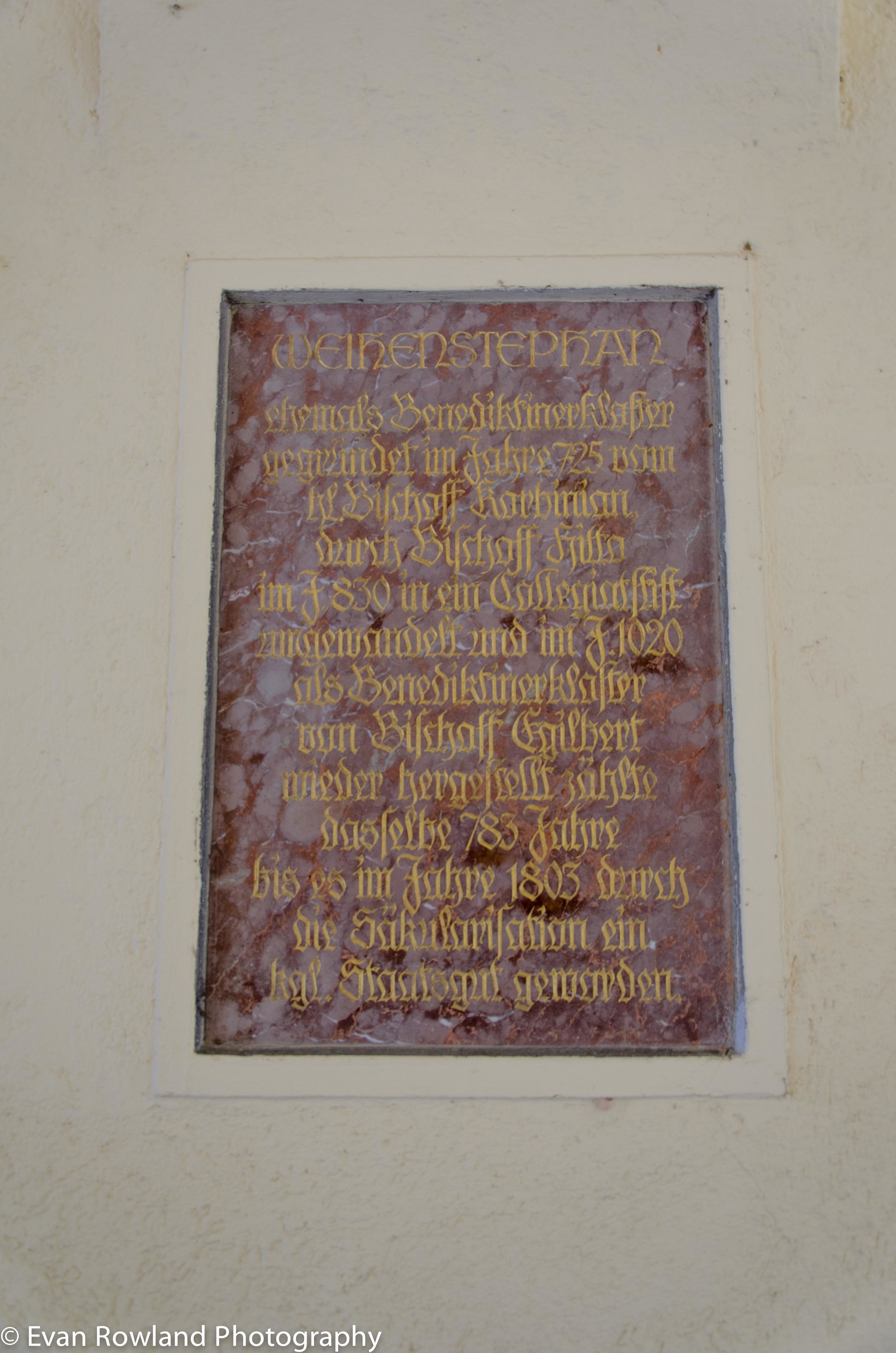

Lisa and I had the great pleasure of attending Oktoberfest this year, and while in Munich managed to tour the oldest brewery in the world, Bayerische Staatsbrauerei Weihenstephan.

Located just north of Munich in Freising, a quick metro ride away, Weihenstephan was easily the most informative brewery tour I have ever been on. One of our guides, Per, the man in the yellow vest pictured above, had been working at the brewery for a while and is going to school to be a Master Brewer. The school is conveniently located at the Weihenstephan complex, right next to the brewery. The guided tour is very open to pictures and Per said they really don't have any secrets. The most interesting thing we learned was that they decoction mash everything in their line of beers. Decoction mashing is taking a portion of your grains, boiling them, and adding them back to the main mash to reach the next temperature step. Originally this was done because grains of yesteryear were lacking in quality and this was a way to extract more sugar. However, modern grains are of higher quality, and typically this type of mash isn't required anymore.

On a homebrew scale this means that your brew day will be much longer than normal. I want to say there is a diminishing return on decoction mashing. I wouldn't mash this way for every single beer we make, but it does help produce nice results. Our second annibeersary was an Oktoberfest beer made by decoction mashing. I'd say it was one of our best beers ever and very similar to the german beers we were drinking there.

Inspired again by Weihenstephaner I am brewing a hefeweizen (full recipe below). Braukaiser has a fantastic write up on decoction mashing here. I mashed in low, around 100, for the acid rest. Pulled the first thick mash to boil and bring the main mash up to 138 for the protein rest. Pulled another thick mash for the saccrification rest at 148 and 158. Using a thin decoction to hit 168 and mash out. Before even getting to the boil my brew day is already 3 hours longer than a normal brew. Some things cannot be rushed.

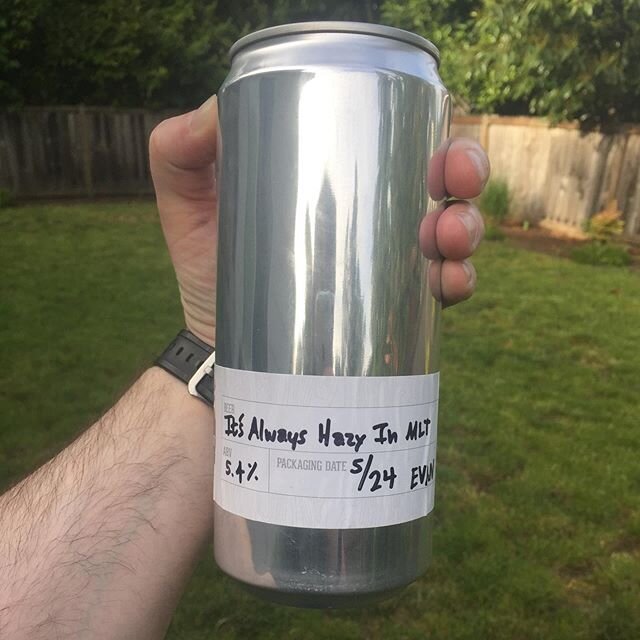

It will cool overnight in the fermentation chamber while the yeast starter picks up. Aiming for a more banana than clove beer we plan on fermenting it open, with cheese cloth covering it. We'll have a review up once its done!

Hefeweizen

7 lbs Wheat malt

3 lbs Pilsner

Wyeast 3068 Weihenstephaner Weizen

.5 oz Hallertauer for 60 and 20

ABV 5.5%

IBU 12